Measures against foreign matter contamination, improved slip resistance, and prevention of sticking achieved. Simultaneously enhancing hygiene management and production efficiency in food factories.

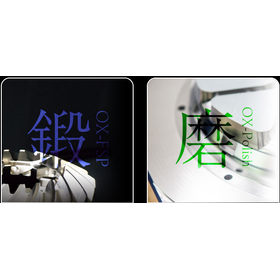

Oxy Co., Ltd.'s "Precision Shot Peening Technology" is a surface modification process developed to enhance the hygiene and efficiency of food factory equipment.

By combining our unique "OX-FSP" and "OX-Polish," we precisely control the microstructure of the surface, improving slip resistance while reducing rolling resistance. This minimizes the adhesion of powders and food materials, reducing the effort required for cleaning. Furthermore, to prevent foreign matter contamination, we treat the metal surface directly without using coatings, eliminating concerns about peeling or leaching, making it safe for the food industry.

Depending on the customer's equipment and application, we can custom design surface conditions such as roughness and gloss. We provide solutions that enhance quality, safety, and productivity for various metal components, including stainless steel.

[Benefits]

■ Weight reduction and thinning of products, reduction of production costs, improvement of production efficiency

■ Durability, wear resistance, low torque, noise reduction, and flowability measures for molds, etc.

■ Extremely high effectiveness as a surface treatment for DLC and coatings

*For more details, please view the PDF by clicking the "Download Catalog" button or feel free to contact us via the "Inquire from Web" button.